Best Tips About How To Build An Induction Furnace

Guide to induction coil design.

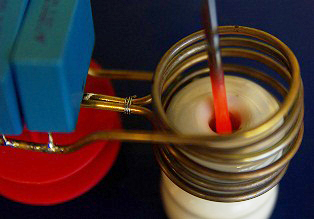

How to build an induction furnace. The smeltable items are put into the two top slots, and then the furnace is supplied with eu. I'll show you the schematics in a little bit. Clean, lay the glass cloth, put the bottom of the furnace, sturdy, flat, the bottom of the furnace is usually about two turns of the induction coil, then put the furnace into it, fill the material, pay.

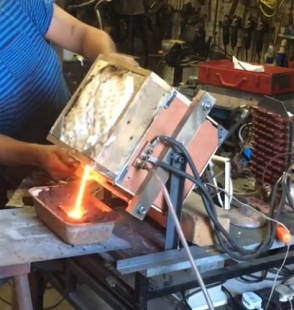

Commercially, they are used for heat treating, brazing, soldering, etc., as well as to melt and forge iron, steel,. The induction unit consists of an iron core in the form of a ring around which a primary induction coil is wound. Note that the furnace can accept both low voltage and medium voltage (up to 128 eu/p).

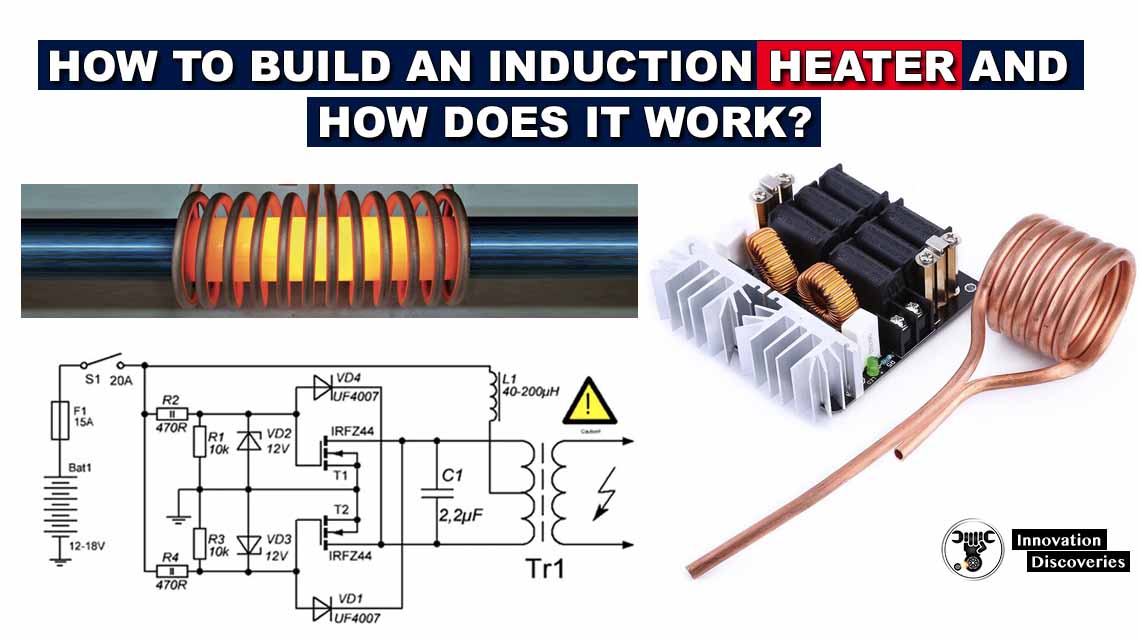

We will use induction to he. 2) an adjustable frequency generator circuit. I have already discussed a few.

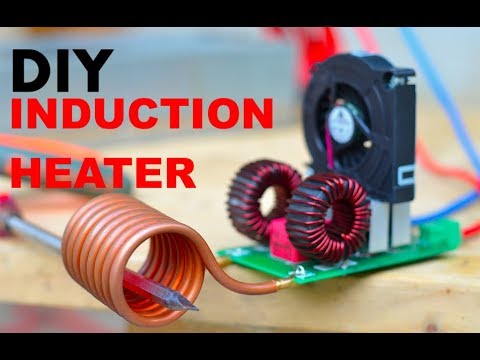

The basic components are the inverter, driver, coupling transformer and rlc tank circuit. Site hoping to find how to build an induction heat treating furnace out of an abandoned microwave domestic oven. Good idea from hard drivecircuit diagram in video:

$2 for 2layer, 5pcs & $5 for 4layer, 5pcs: Let's start with the inverter. 5 basic tips for designing your induction heating coil.

Diy powerful induction heater step 1: This brochure provides a guide for everything you need to design the optimal coil for the best performance from your induction heating system. Higher flux density near the heating area means a higher current is generated in the part.

The two bare basic things required for building any induction cookware are: The many responses from apparently knowledgable guys were 100. When designing the furnace body, it is necessary to select the appropriate furnace body size and induction coil to ensure the smooth flow of current and improve the.

There are multiple methods of heating metals, one of which is induction. This assembly forms a simple transformer in which the molten metal loops.